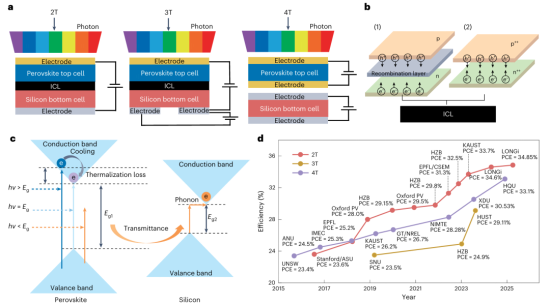

Against the backdrop of accelerating global energy transition, photovoltaic technology is continuously pushing toward higher efficiency, lower costs, and better stability. As single-junction photovoltaic cell efficiency gradually approaches the theoretical limit,perovskite/silicon tandem solar cells (TSCs), with a breakthrough certified efficiency of 34.85% and a theoretical potential of up to 45.1%,have become the research focus of next-generation photovoltaic technology, bringing new hope for breaking the efficiency bottleneck. However, the path to industrialization is not smooth, facing three core challenges:a gap between actual efficiency and theoretical limits, insufficient long-term operational stability, and immature large-area manufacturing processes.

Q

What is perovskite?

Perovskite is not a mineral but a general term for materials with a specific crystal structure, named after the calcium titanate compound first discovered in perovskite ore. Perovskite has very high absorption and conversion efficiency for visible light, capable of efficiently converting light energy into electrical energy. Currently, perovskite cells mainly have two technical routes: single-junction and tandem.

A

On August 14,Associate Professor Bai Yang’s team from the Faculty of Materials Science and Energy Engineering at Shenzhen University of Advanced Technology, in collaboration with research teams from Hong Kong Polytechnic University, the University of North Carolina at Chapel Hill, and other institutions, published a review paper in the top international journalNature Photonics, systematically analyzing and deeply examining the technical bottlenecks and solutions for perovskite/silicon tandem solar cells in the three key dimensions ofefficiency improvement, stability enhancement, and large-scale manufacturing,providing a systematic technical roadmap for building a commercial closed loop for this frontier technology.

a. Structural diagram of perovskite/silicon tandem solar cells; b. Diagram of the intermediate connection layer of tandem cells; c. Energy band diagram of perovskite/silicon tandem solar cells; d. Efficiency evolution diagram of perovskite/silicon tandem solar cells.

1,Focusing on Efficiency Breakthroughs:Addressing Optical and Electrical Loss Challenges

Currently, the laboratory-certified efficiency of perovskite/silicon tandem cells has surpassed 35%, but there is still significant room for improvement compared to its theoretical limit. Studies indicate:Optical loss(insufficient light capture) andelectrical loss(non-radiative recombination) are the main limiting factors.

(1) In terms of optical management optimization,the research team proposed several innovative strategies: Develop efficient anti-reflective coatings to reduce sunlight reflection losses; implement textured interface engineering to enhance the light-trapping effect through special texture designs, allowing sunlight to be repeatedly absorbed inside the cell; optimize transparent conductive electrode (TCE) and interconnect layer designs to balance high light transmittance with low resistance, achieving a balance between transparency and conductivity.

(2) In terms of electrical performance improvement,suppressing non-radiative recombination is the core task, particularly addressing bulk defects and interface non-radiative recombination issues in wide-bandgap perovskite materials. The team effectively improved carrier transport characteristics and reduced power “leakage” by precisely controlling crystallization kinetics and applying multifunctional molecular additives. At the same time, using novel transport materials such as self-assembled monolayers (SAM) achieved better energy level alignment, further reducing interface voltage losses.

2,Tackling Large-Scale Manufacturing:Exploring Process Compatibility and Cost Balance

Transforming laboratory results into industrial reality, large-scale manufacturing is an unavoidable key step. The core challenge in the industrialization of perovskite/silicon tandem solar cells lies in how to achieveuniform conformal coverageof large-area, high-quality perovskite thin films ontextured silicon substrates, and how to efficiently integrate with existing silicon cell production lines.

Currently, large-scale manufacturing has three main technical routes:

Solution method:Lower cost, but facing challenges in controlling large-area film uniformity, with some solvents posing environmental and toxicity issues;

Vacuum deposition method:Can produce high-quality films, but at a high cost, and difficult to integrate with additive engineering;

Hybrid deposition technology:Combines the high-quality advantages of vacuum coating with the flexibility and cost advantages of solution processing, demonstrating good process compatibility and economic potential, becoming an important exploration direction for large-scale manufacturing.

3,Enhancing Long-Term Stability:Building the “Lifeline” for Commercialization

Long-term operational stability is the biggest bottleneck in the commercialization process of perovskite/silicon tandem solar cells.Wide-bandgap perovskites are prone to halide phase separation under humid heat or light stress, leading to accelerated device performance degradation. In response, the team systematically improved stability from three aspects: enhancing intrinsic material properties, strengthening encapsulation protection, and establishing evaluation systems.

In terms of enhancing intrinsic stability,through lattice stress regulation and redox engineering strategies, effectively suppressing ion migration rates, enhancing material stability from the source.

In terms of encapsulation protection,developing encapsulation materials with high water and oxygen barrier performance and excellent mechanical stress regulation capabilities, and precisely controlling interlayer coefficient of thermal expansion (CTE) matching to prevent encapsulation failure due to thermal cycling.

At the same time, the team calls forestablishing standardized outdoor testing platformsto systematically study the impact of real environmental factors such as temperature cycling and dynamic spectra on device degradation mechanisms, providing a scientific basis for lifespan assessment and prediction.

4,Looking to the Future:Multidimensional Innovation Promotes Industrialization

The paper points out that future technical breakthroughs in perovskite/silicon tandem solar cells will focus on three directions:

Developing new perovskite materials:Developing new perovskite material systems with high phase stability and resistance to ion migration;

Innovating device structures:Such as designing bifacial power generation architectures to maximize energy capture efficiency;

Building lifespan prediction models:Integrating accelerated aging tests with long-term outdoor validation data to build reliable lifespan prediction models.

The ultimate goal is to achieve coordinated development ofhigh efficiency, low cost, and high reliability, building a complete technological innovation system.

5,Leading Systematic Review, Drawing Industrialization Blueprint

Associate Professor Bai Yang’s team at Shenzhen University of Advanced Technology has been deeply engaged in the field of new energy materials and devices for many years. This published systematic review not only deeply analyzes the key technical paths and challenges for the industrialization of perovskite/silicon tandem solar cells but also highlights the international academic influence of Chinese research teams in this field, providing important theoretical guidance and solution references for accelerating the commercialization process of this technology in the global photovoltaic industry.

Associate Professor Bai Yang from Shenzhen University of Advanced Technology, Professors Yang Guang and Li Gang from Hong Kong Polytechnic University, and Professor Huang Jinsong from the University of North Carolina at Chapel Hill are the co-corresponding authors of the paper; Professor Yang Guang from Hong Kong Polytechnic University, Dr. Deng Chunyan from Shenzhen University of Advanced Technology, and Professor Li Chongwen from Southeast University are the co-first authors of the paper.

Paper link: https://www.nature.com/articles/s41566-025-01732-y (click “Read Original” to view)